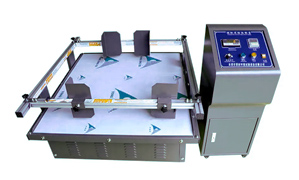

Shock tests, are performed to assure that material can withstand the relatively infrequent non-repetitive shocks or transient vibrations encountered in handling, transportation and service environments. Shock tests are also used to measure an item’s fragility, so that packaging may be designed to protect it, if necessary, and to test the strength of devices that attach equipment to platforms that can crash.

Mechanical shocks will excite an equipment item to respond at both forced and natural frequencies. This response, among other things, can cause:

Failures due to increased or decreased friction, or interference between parts.

Changes in dielectric strength, loss of insulation resistance, vibrations in magnetic and electrostatic field strength.

Permanent deformation due to overstress.

More rapid fatiguing of materials (low cycle fatigue)

Scope of services: household appliances, auto parts, power tools, marine/fishing equipment, etc.

Standard: GB/T 2423.5 GB/T 2425.6 IEC 60068-2-27 etc.

-

Contact us

- Spark Lab - Shenzhen

- Mr. Zhang

- 13902479643

- sparkrz@spark-oe.com